The SD60ACC Locomotive: A Modern Solution for Rail Transportation

Introduction

In today’s rapidly evolving transportation landscape, the demand for efficient, sustainable, and powerful locomotives is more pressing than ever. Rail operators are increasingly under pressure to meet stringent emissions standards while simultaneously managing the high freight demands of a growing economy. The SD60ACC locomotive stands out as a modernized version of the classic EMD SD60 series, meticulously designed to address these challenges. By integrating upgraded AC traction motors, adhering to emission regulations, and enhancing fuel efficiency, the SD60ACC emerges as a versatile solution poised to transform rail operations.

What is the SD60ACC?

The SD60ACC is a significant upgrade over the older SD60 locomotives, representing a thoughtful rebuild that replaces the original DC traction systems with advanced AC motors. This modernization enhances the locomotive’s reliability, especially when it comes to hauling heavy freight over long distances. Moreover, the SD60ACC aligns with contemporary environmental standards, ensuring that rail operators can meet both operational demands and sustainability goals.

Technical Specifications

The SD60ACC boasts impressive technical specifications that underscore its capability in demanding rail operations:

- Horsepower: 3,800 HP powered by an EMD 16-710G3B engine

- Traction Motors: Upgraded AC motors that offer improved performance and reliability

- Fuel Capacity: 4,900 gallons, enabling extended operational range without frequent refueling

- Top Speed: 70 mph (113 km/h), allowing for efficient travel on both short and long-haul routes

- Weight: 415,000 lbs (188,000 kg), providing stability and traction for heavy loads

- Operational Range: Specifically designed for long-haul freight and intermodal transport

These specifications highlight the SD60ACC’s ability to manage demanding rail operations while minimizing downtime, enhancing productivity across the board.

Environmental Compliance and Sustainability

The SD60ACC is built with a commitment to environmental sustainability, meeting the EPA Tier 1+ emissions standards. This commitment is crucial as rail companies face increasing scrutiny regarding their environmental impact. By incorporating optional Tier 2 retrofit kits, the SD60ACC significantly reduces nitrogen oxide (NOx) emissions and particulate matter, making it an attractive option for environmentally conscious operators.

Fuel Efficiency

One of the standout features of the SD60ACC is its fuel efficiency. Compared to its predecessors, the SD60ACC offers a notable improvement of 10-15% in fuel economy, a result of its advanced traction motors and emissions control systems. This enhancement not only lowers operational costs but also aligns with the industry’s push for greener technologies.

Carbon Reduction

The impact of the SD60ACC on carbon emissions is substantial. A single SD60ACC locomotive can contribute to a reduction of several tons of CO2 emissions annually when compared to older models. This capacity for carbon reduction is increasingly essential as rail companies aim to achieve ambitious sustainability targets and contribute to global efforts to combat climate change.

Real-World Applications

The versatility and efficiency of the SD60ACC are evident across various rail networks. Some notable real-world applications include:

- Norfolk Southern: The SD60ACC is extensively utilized for heavy freight and intermodal transport across the Midwest, where its reliability and power shine.

- CSX Corporation: This locomotive is deployed for mixed freight operations on long-haul routes, where its fuel efficiency and compliance with emission standards are critical.

- Canadian National (CN): Currently testing its viability for cross-border services between the U.S. and Canada, the SD60ACC is gaining traction in international rail operations.

These examples illustrate the locomotive’s adaptability and performance in diverse rail scenarios, confirming its status as a crucial asset in modern rail operations.

Historical Evolution of the SD60ACC

The journey of the SD60ACC is a fascinating reflection of technological advancement within the rail industry. It builds on a rich legacy from earlier EMD SD60 models, showcasing a commitment to improving both functionality and environmental impact:

- SD60: Launched in the 1980s, the original SD60 focused on power and reliability but lacked the advanced emissions control technologies that are standard today.

- SD60M: This variant introduced wider cabs for enhanced crew comfort, catering to the long-distance operational needs of the workforce.

- SD60I: Featured additional noise insulation, further improving the operator experience during lengthy journeys.

- SD60ACC: This modern iteration incorporates cutting-edge AC motors, digital control systems, and rigorous emissions compliance measures, transforming earlier models into efficient and sustainable machines.

This evolutionary trajectory underscores the ongoing technological progress that the SD60ACC represents in the rail industry.

Maintenance Challenges and Costs

While the SD60ACC offers numerous advantages, it also introduces certain operational challenges that rail operators must navigate:

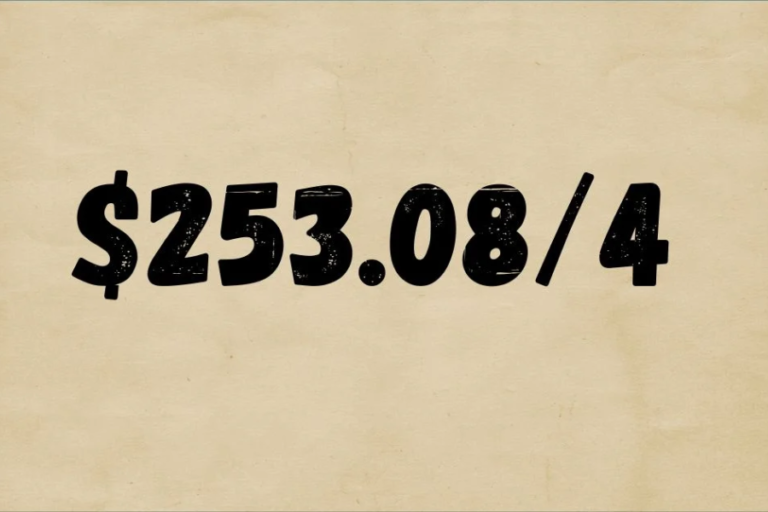

Higher Maintenance Costs

The transition to modern electronics and AC traction systems necessitates specialized technicians for maintenance. This can lead to increased operational costs, as not all existing maintenance crews may have the expertise required to service these advanced systems.

Parts Availability

As rail operators integrate newer technologies, the availability of specific parts, such as AC motor assemblies, may become limited. This scarcity can lead to occasional downtime, affecting the efficiency of rail operations.

Training Requirements

To effectively operate and maintain the SD60ACC, crews must undergo specialized training. This requirement is essential for familiarizing operators with the new control systems and emissions technologies, ensuring safe and efficient locomotive operation.

These challenges highlight the importance of proactive maintenance strategies and the necessity for skilled personnel in managing modern locomotives.

Future Trends in Locomotive Technology

The SD60ACC serves as a stepping stone for future innovations in rail technology. As the industry continues to evolve, several exciting trends are emerging:

Hybrid Technology

The development of hybrid locomotives that combine battery-electric systems with diesel engines is gaining momentum. This technology promises to further reduce emissions, aligning with global efforts to create more sustainable transportation solutions.

IoT Integration

The incorporation of Internet of Things (IoT) technology into locomotives is on the rise. By installing sensors that monitor locomotive health and performance, operators can access real-time data, enhancing decision-making and predictive maintenance strategies.

Autonomous Operations

Looking ahead, the potential for semi-autonomous control in locomotives represents a transformative shift in rail operations. This advancement could lead to improved efficiency, safety, and reduced reliance on human operators for routine tasks.

These trends reflect the SD60ACC’s alignment with the future of rail transportation, positioning it as a model for the next generation of locomotives..

Key Takeaways

The SD60ACC locomotive is a remarkable embodiment of progress in the rail industry, offering several key advantages:

- Efficiency: With significant improvements in fuel economy and operational performance, the SD60ACC stands as a model of efficiency in freight transport.

- Environmental Compliance: Meeting EPA Tier 1+ standards with options for future upgrades to Tier 2 compliance, the locomotive is designed with sustainability in mind.

- Versatility: The SD60ACC’s capacity to operate in both freight and passenger services provides operational flexibility that is highly valued in the rail sector.

- Challenges: While offering numerous benefits, the SD60ACC requires specialized maintenance expertise, and parts availability can pose challenges.

- Future Potential: With trends like IoT integration and hybrid technologies on the horizon, the SD60ACC is positioned for continuous improvement in performance and sustainability.

These key points summarize the locomotive’s strengths and limitations, reinforcing its value in modern rail operations.

Conclusion

In summary, the SD60ACC locomotive embodies a harmonious blend of power, sustainability, and innovation. With its advanced AC traction motors, enhanced fuel efficiency, and rigorous emissions compliance, it presents a compelling solution for rail companies striving to modernize their fleets. Despite the challenges associated with maintenance and training, the locomotive’s versatility and forward-thinking technology ensure that it will remain an essential asset in the rail industry for years to come. As rail operators continue to seek ways to improve efficiency and reduce their

Facts

- Model: SD60ACC

- Horsepower: 3,800 HP (EMD 16-710G3B engine)

- Traction Motors: Upgraded AC motors

- Fuel Capacity: 4,900 gallons

- Top Speed: 70 mph (113 km/h)

- Weight: 415,000 lbs (188,000 kg)

- Operational Range: Designed for long-haul freight and intermodal transport

- Environmental Compliance: Meets EPA Tier 1+ standards; optional Tier 2 retrofit available

- Fuel Efficiency: 10-15% improvement over older SD60 models

- Carbon Reduction: Can reduce CO2 emissions by several tons annually

- Real-World Usage: Employed by Norfolk Southern, CSX Corporation, and Canadian National (CN)

FAQs

1. What is the SD60ACC? The SD60ACC is a modernized locomotive built from the original EMD SD60 series, featuring upgraded AC traction motors that improve performance and reliability, especially for heavy freight hauling over long distances.

2. How does the SD60ACC improve fuel efficiency? The SD60ACC offers a 10-15% improvement in fuel economy compared to older models, due to its upgraded AC traction motors and advanced emissions control systems.

3. What are the environmental compliance standards for the SD60ACC? The SD60ACC meets EPA Tier 1+ emissions standards and can be retrofitted to comply with Tier 2 standards, significantly reducing nitrogen oxide (NOx) emissions and particulate matter.

4. Where is the SD60ACC commonly used? The SD60ACC is utilized extensively in various rail networks, including heavy freight and intermodal transport for companies like Norfolk Southern and CSX Corporation, and is being tested by Canadian National for cross-border services.

5. What maintenance challenges are associated with the SD60ACC? While the SD60ACC has many advantages, it requires specialized maintenance due to its modern electronics and AC traction systems, which can lead to higher operational costs and parts availability issues.

6. What future trends are expected for locomotives like the SD60ACC? Future trends may include hybrid technology that combines battery-electric systems with diesel engines, IoT integration for real-time monitoring of locomotive performance, and potential for semi-autonomous operations to enhance efficiency and safety.

7. How does the SD60ACC compare to similar locomotives? In comparison to similar locomotives like the SD70ACe and GE AC4400CW, the SD60ACC offers competitive horsepower, high fuel efficiency, and compliance with EPA Tier 1+ standards, making it suitable for various freight applications.